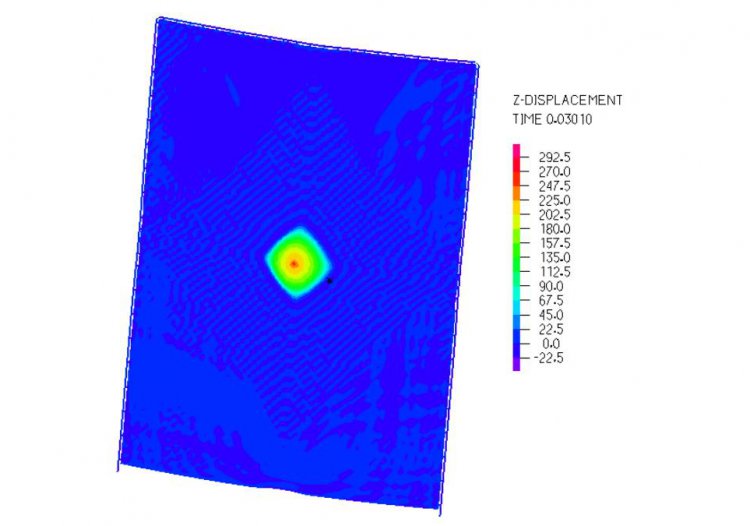

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

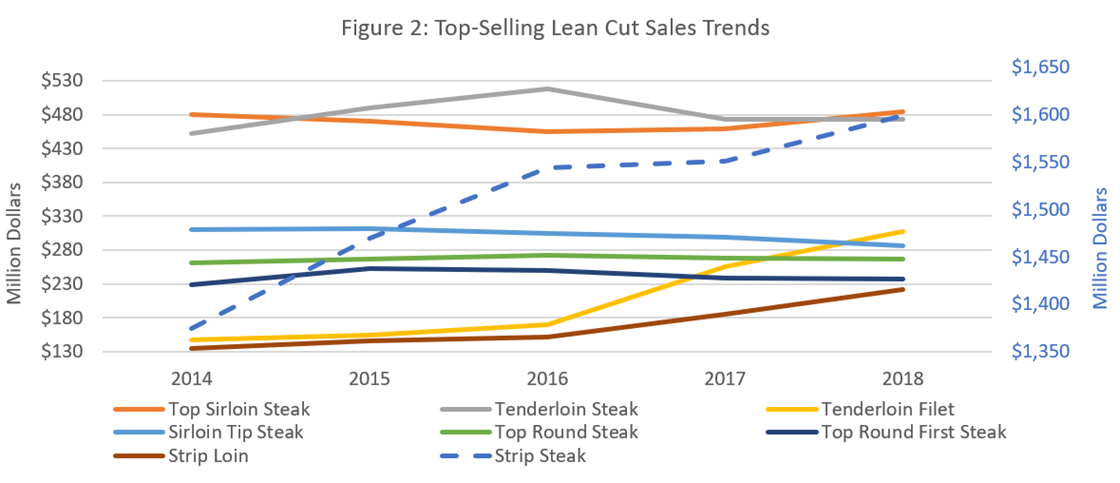

Numerical simulation and experimental study on cold extrusion process for clutch outer gear hub with inner tooth shapes

PDF) Minimisation of the damage in the extrusion process of titanium alloy blades using the response surface method and finite element analysis

Numerical simulation and experimental study on cold extrusion process for clutch outer gear hub with inner tooth shapes

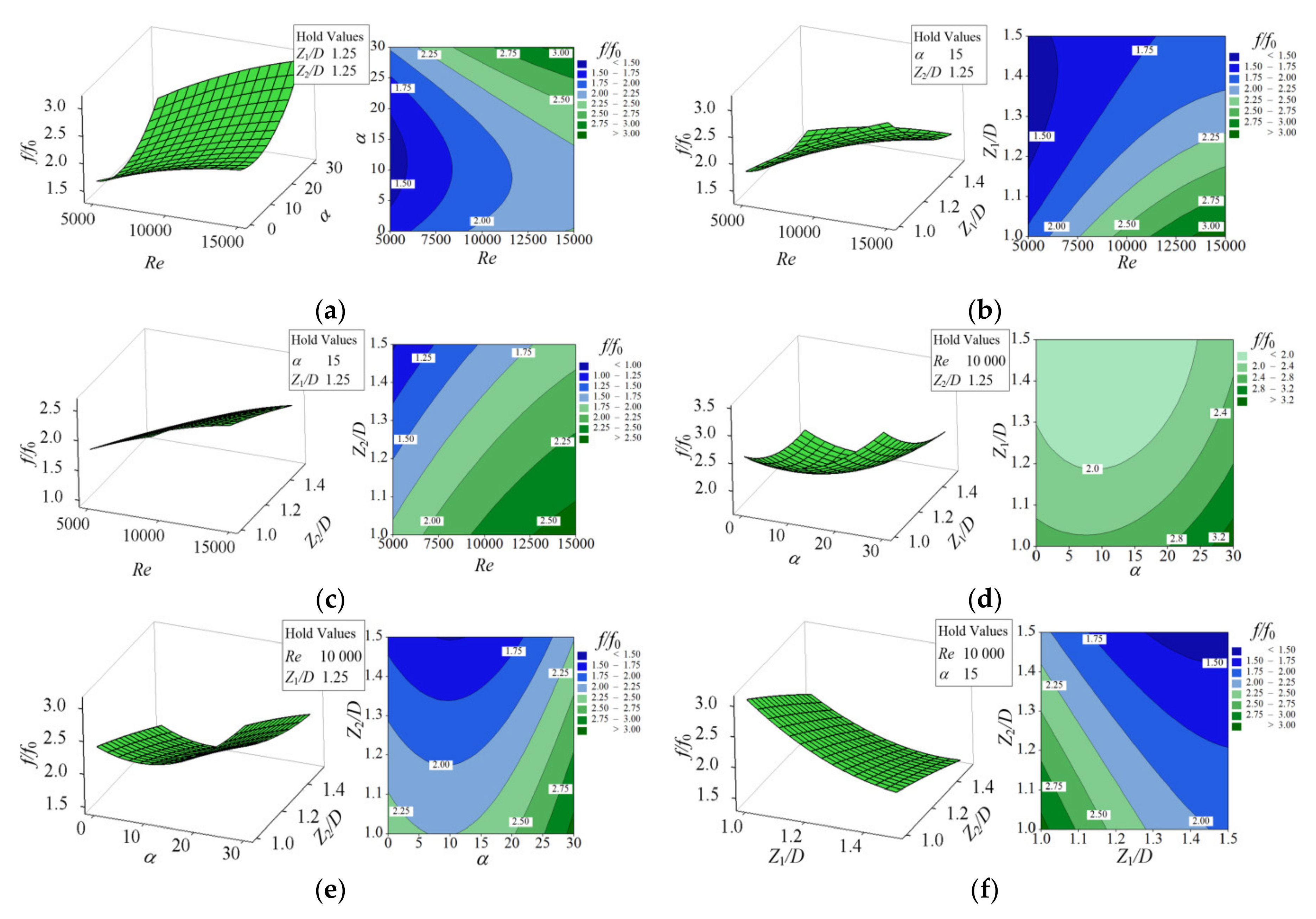

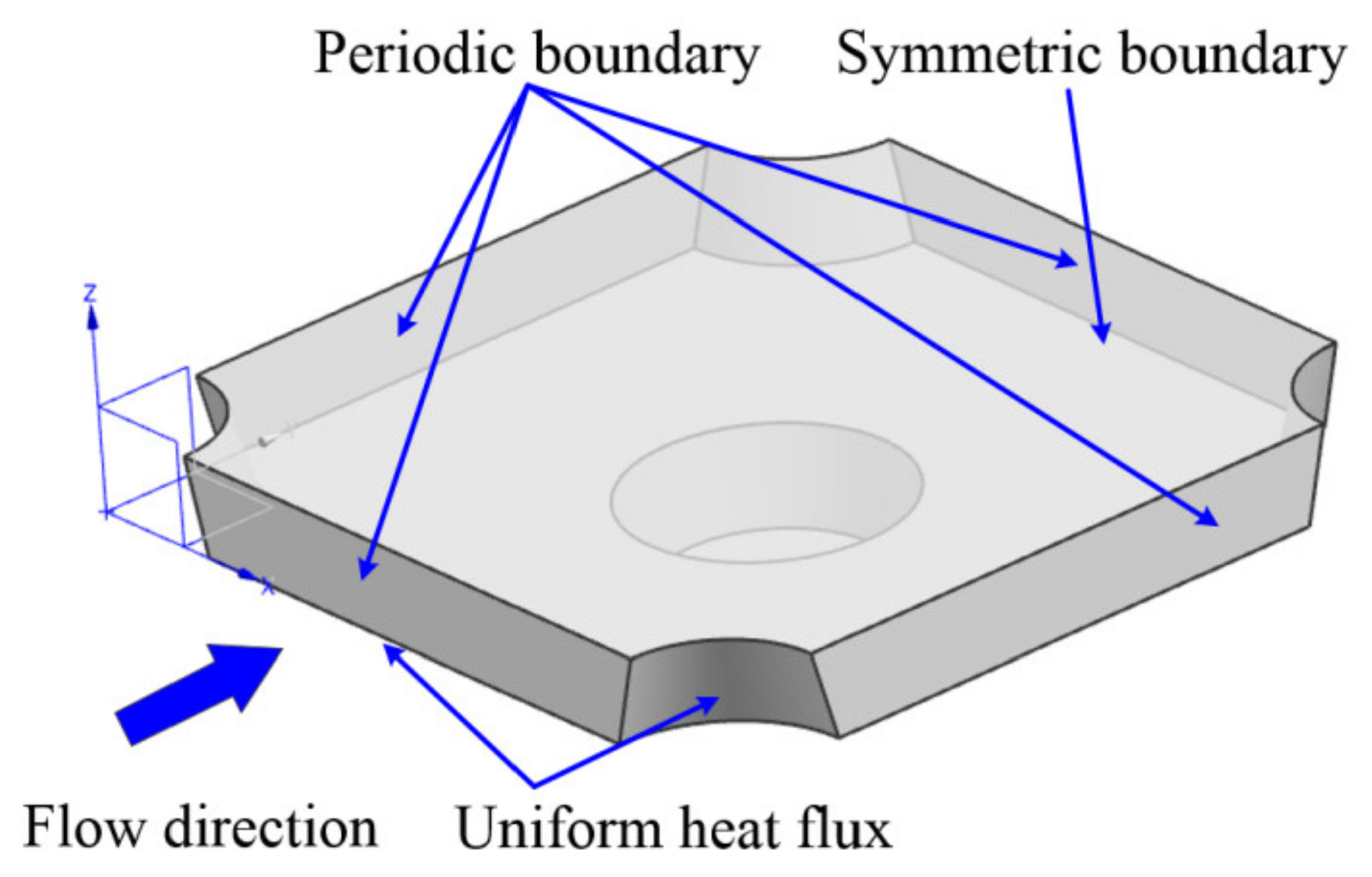

Energies, Free Full-Text

Action Recognition, Tracking, and Optimization Analysis of Training Process Based on SVR Model and Multimedia Technology

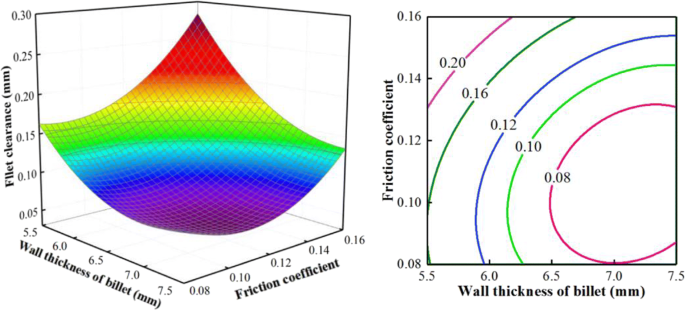

Modeling and optimization of cold extrusion process by using response surface methodology and metaheuristic approaches

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

Multi-objective optimization of GFRP injection molding process parameters, using GA-ELM, MOFA, and GRA-TOPSIS

Energies, Free Full-Text

Modeling and optimization of cold extrusion process by using response surface methodology and metaheuristic approaches

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches